K19

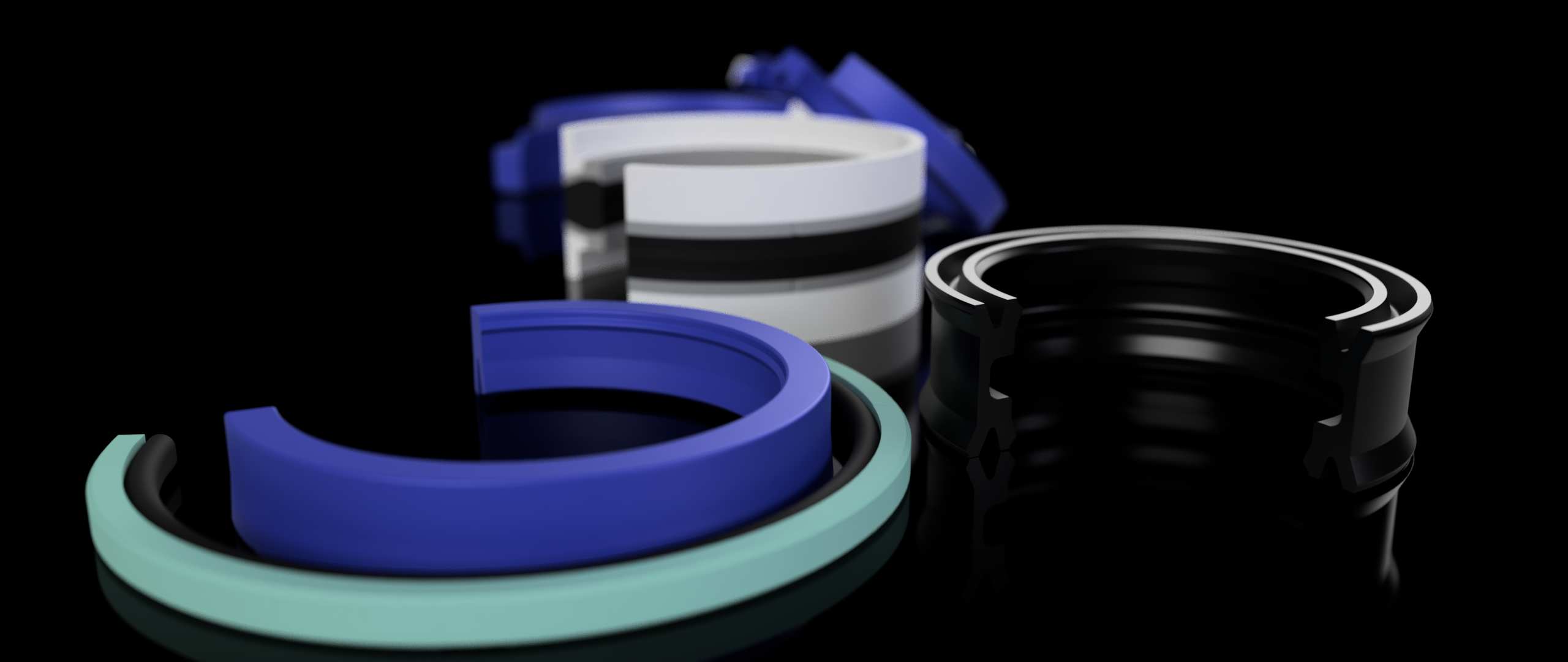

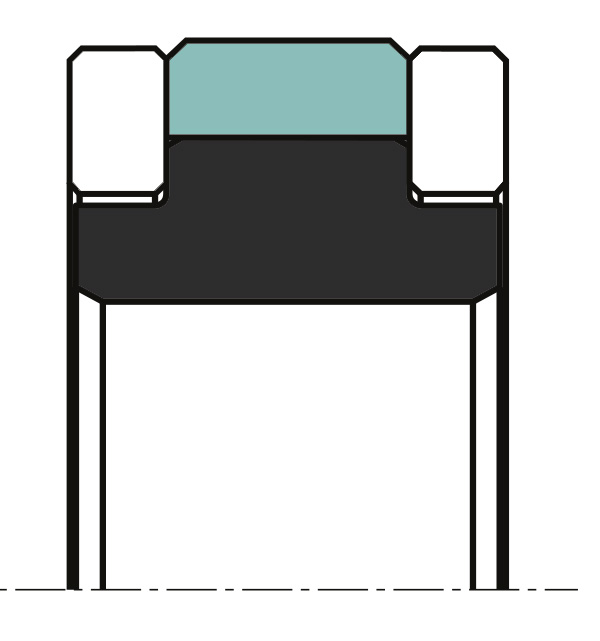

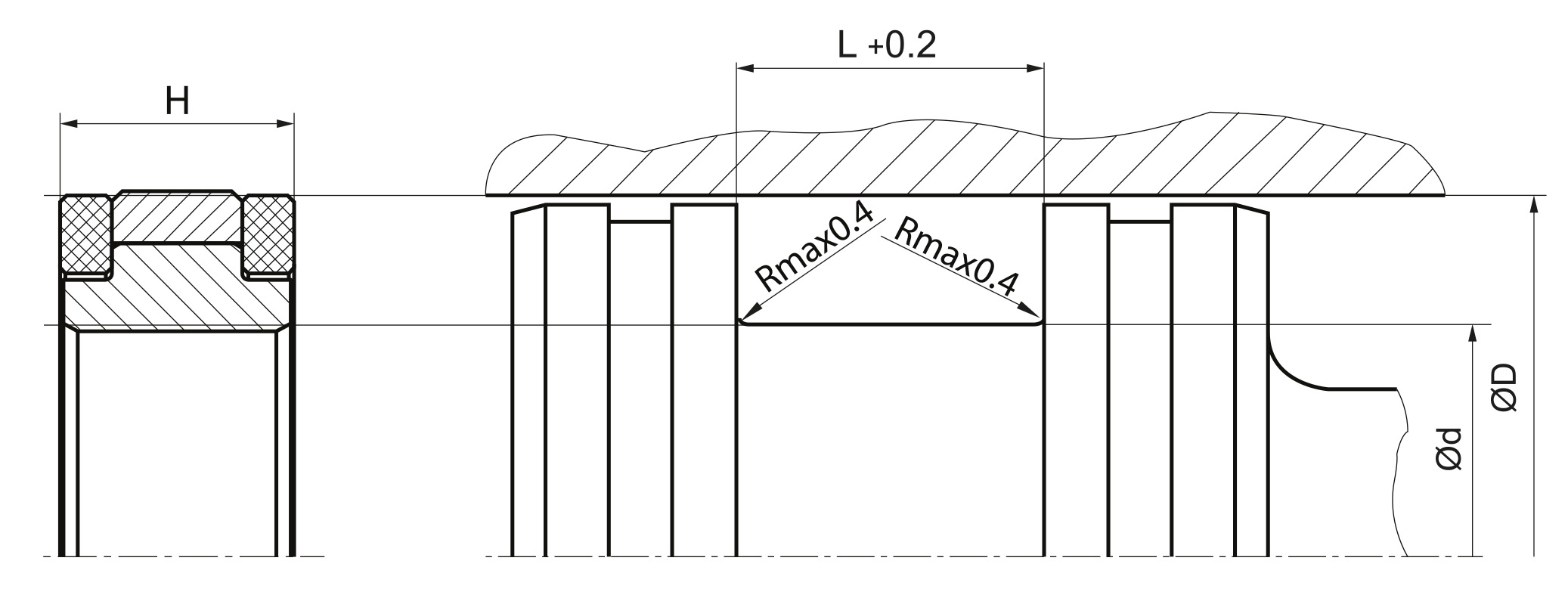

K 19 is a four piece double acting heavy duty compact seal which consists of one PTFE bronze profile ring, one elastomeric nitrile rubber pre-load sealing element and two thermoplastic back-up rings.

-

High sliding speed

-

Low friction , free of stick-slip

-

Simple groove design

-

Long service life

-

Very good sealing performance even with pressure peaks

-

High resistance to abrasion

-

Increased clearance possible

Mining equipment, construction machinery and earth moving equipment.

The elastomeric ring should be assembled into the one-piece piston firstly, and then special mixture PTFE should be assembled with a special assembly tool, lastly the split guide rings should be installed. The required insertion chamfers on the piston and cylinder bore should be de-burred and rounded. It is very important that the assembly tools must be of soft material and have no sharp edges. Before installation the sealing element must be oiled with system oil.

For special applications that require high temperatures, piston seal is being manufactured with FKM pre-load component , pure PTFE back-up rings and special mixture PTFE profile ring. Due to the design, K19 can be used up to shock pressures of 600 bar safely. The permissible sealing gap values of K19 heavy duty piston seal is given in the below table.

| Material | Code |

| NBR 80 SHORE A | NBR8001 |

| PTFE | PT6003 |

| POM | PM9901 |

| Surface roughness | Ra | Rmax |

| Sliding Surface Ød | ≤0.2 μm | ≤2.0 μm |

| Groove Base ØD | ≤1.6 μm | ≤6.3 μm |

| Groove Flanks | ≤3.2 μm | ≤16 μm |

PERMISSIBLE SEALING GAP

| Pressure(Bar) | Smax (mm) |

| P≤350 | 0.45 |

| 350<P≤600 | 0.25 |

OPERATING CONTITIONS

| Media | Mineral oils (DIN 51524) | HFA HFB | HFC |

| Temperature | -30 °C +105 °C | +5 °C +60 °C | -30 °C +60 °C |

| Pressure | ≤400 bar | ≤400 bar | ≤400 bar |

| Speed | ≤1.5 m/sec | ≤1.5 m/sec | ≤1.5 m/sec |