K35

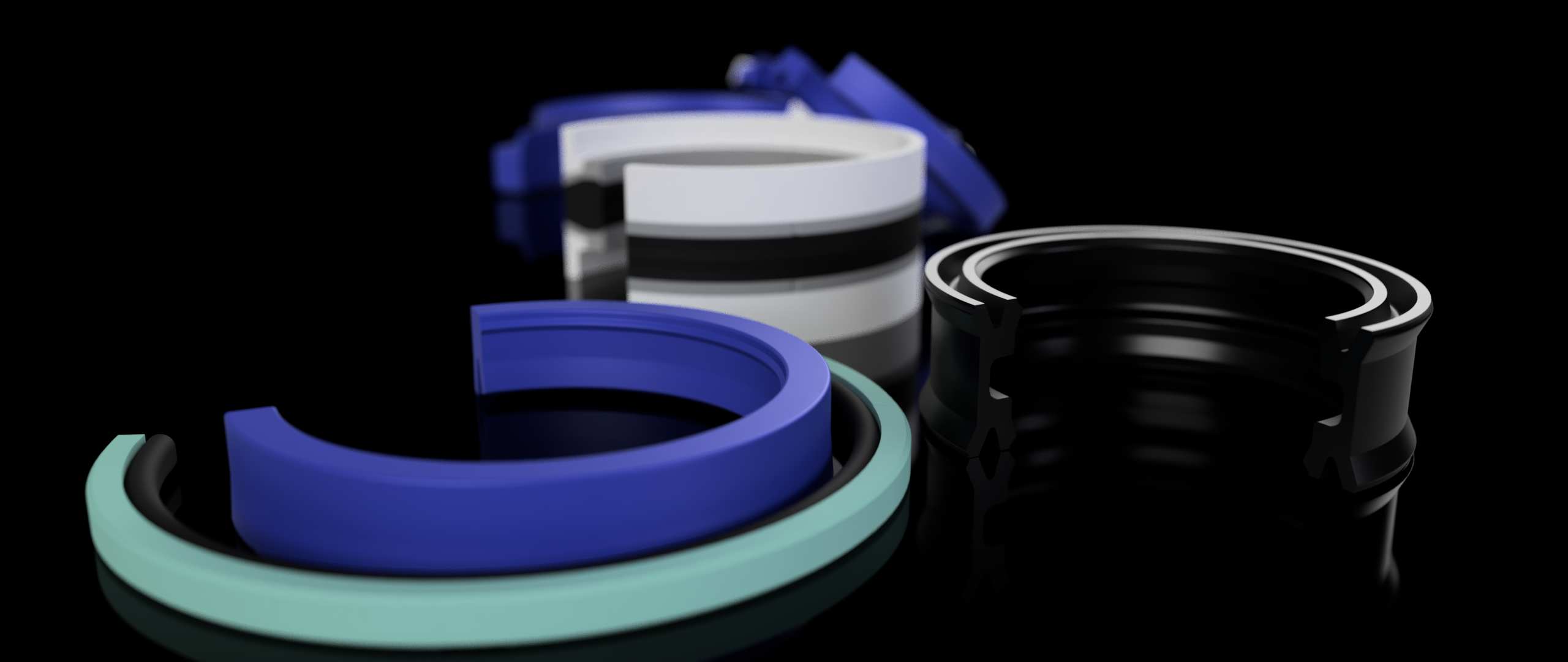

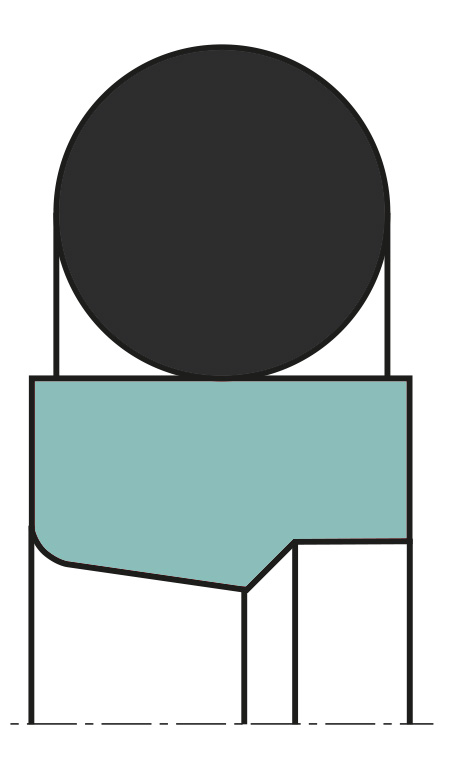

K35 is a two piece single acting rod seal which consists of one special mixture PTFE profile ring and an o-ring as energizing element.

-

Low friction, free of stick-slip

-

Due to the special profile it can be used in pair or in front of the u-ring

-

Long service life

-

High sliding speed

-

Wide range of temperature and chemicals depending on the o-ring material

-

Minimum static and dynamic friction coefficient for a minimum energy loss and operating temperature

-

Simple groove design and low axial housing heights

Injection moulding machines, fork-lift trucks, loading platforms, cranes, agricultural machinery, hydraulic breakers and servo cylinders.

We recommend using special assembly tool (See section; Hydraulic Sealing Elements General Installation Information). It is very important that the assembly tools must be of soft material and have no sharp edges. Before installation the sealing element must be oiled with system oil.

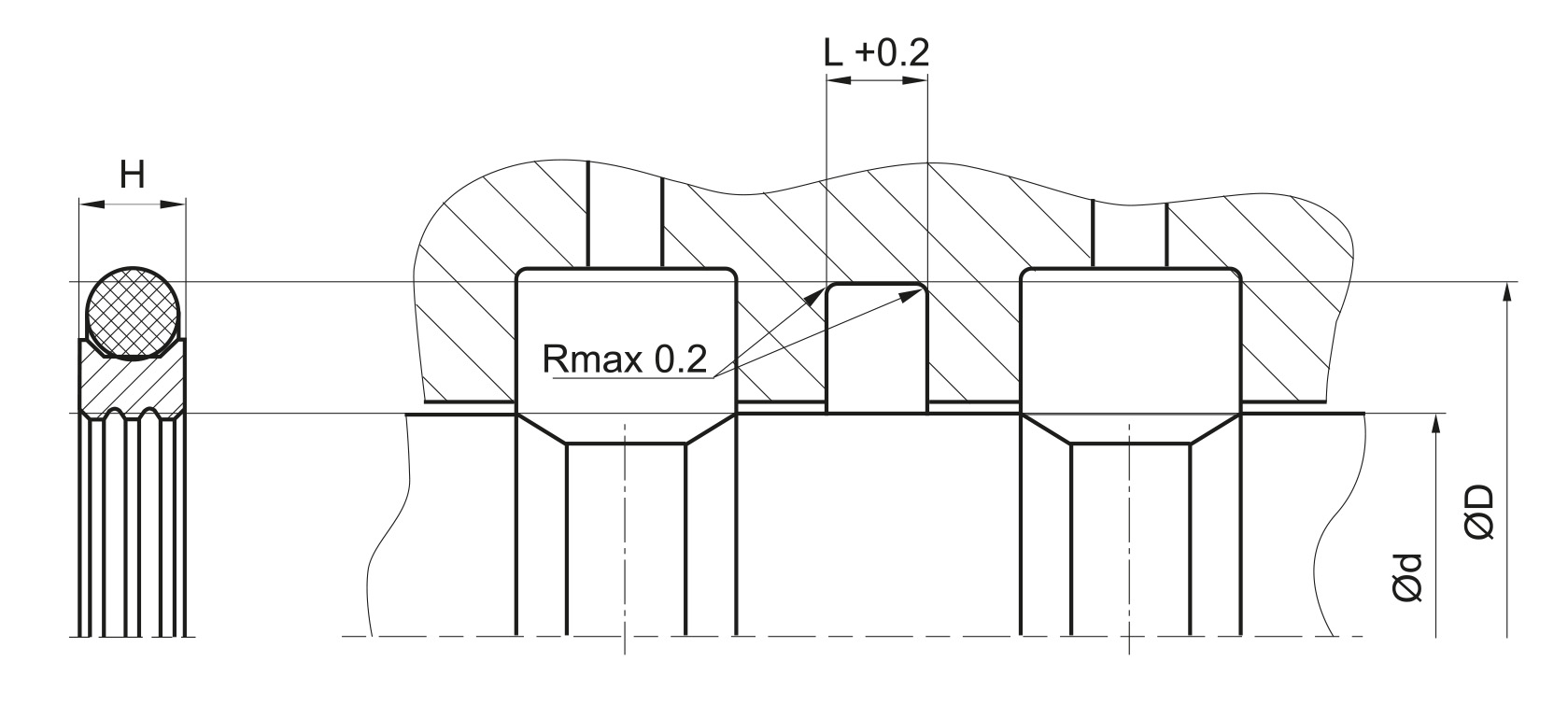

K35 type of rod seal can be also used with double lip wipers. For special applications that require high temperatures or resistance to chemicals, piston seal is being manufactured with special mixture PTFE and FKM material. For heavy duty applications and high pressures the tolerances should change to H8/f8 and please contact the customer service to choose the suitable sealing element. The permissible sealing gap values of K35 rod seal is given in the below table.

| Material | Code |

| NBR 70 SHORE A | NBR7001 |

| PTFE | PT6003 |

| Surface roughness | Ra | Rmax |

| Sliding Surface Ød | ≤0.2 μm | ≤2.0 μm |

| Groove Base ØD | ≤1.6 μm | ≤6.3 μm |

| Groove Flanks | ≤3.2 μm | ≤15 μm |

Permissible sealing gap

| B (mm) | Smax (mm) | ||

| 150 bar | 250 bar | 400 bar | |

| 2.2 | 0.25 | 0.15 | 0.10 |

| 3.2 | 0.35 | 0.20 | 0.10 |

| 4.2 | 0.35 | 0.20 | 0.15 |

| 6.3 | 0.45 | 0.25 | 0.15 |

| 8.1 | 0.55 | 0.30 | 0.20 |

| 8.1 | 0.55 | 0.30 | 0.20 |

OPERATING CONTITIONS

| Media | Mineral oils (DIN 51524) | HFA HFB | HFC |

| Temperature | -30 °C +105 °C | +5 °C +60 °C | -30 °C +60 °C |

| Pressure | ≤400 bar | ≤400 bar | ≤400 bar |

| Speed | ≤5.0 m/sec | ≤5.0 m/sec | ≤5.0 m/sec |

Szeretne többet megtudni a termékről?

E-mail

info@intramark.hu

Telefon

+36 52 540 555

+36 20 913 4498

Nyitvatartás

H-CS: 8:00 – 16:30

P: 8:00 – 16:00

Intramark Kft. központ

4031 Debrecen,

Köntösgát sor 10.